-

×

×Acetic Flavour Standard (Acetic Acid)

1 × £75.00 GBP

Subtotal:

£75.00 GBP

The Cooked Onion (Dimethyl Trisulphide) flavour standard helps train professional beer tasters to recognise and scale the intensity of the onion character. Onion or Dimethyl Trisulphide (DMTS) is one of the sulphur flavours that occur as part of the brewing process in beer. It can be produced by sulphur-containing amino acids during wort boiling and from the oxidation of Methanethiol.

Generally, carbon dioxide purges Dimethyl Trisulfide (DMTS) during fermentation. The flavour threshold of DMTS in beer is 40 ng/L.

We ship globally – shipping costs may apply depending on your region

Minimum Order: £275

What is Cooked Onion (DMTS) Flavour?

Cooked Onion flavour, also known as Dimethyl trisulfide (DMTS), is a sulphur-containing flavour that emerges during the brewing process. It is often described as:

DMTS is naturally formed in beer during wort boiling and fermentation, originating from sulphur-containing amino acids or the oxidation of Methanethiol. Its detection threshold in beer is extremely low—around 40 ng/L—making it a subtle but significant flavour note for professional tasters.

What Causes Cooked Onion (Dimethyl Trisulphide) Off-Flavour?

The Cooked Onion off-flavour in beer is primarily caused by:

1. Brewing Process:

2. Fermentation:

3. Non-Alcoholic Beverages:

Using the Cooked Onion Flavour Standard for Sensory Training

The Cooked Onion (DMTS) flavour standard is widely used in sensory training to help professionals:

How to Recognise Cooked Onion (Dimethyl Trisulphide) Flavour: Sensory Terms

When identifying the Cooked Onion flavour, tasters often describe it using the following sensory terms:

These descriptors help pinpoint the presence of DMTS and differentiate it from other sulphur-based flavours.

What are the Professional Applications of the Cooked Onion Flavour Standard?

The Cooked Onion Flavour Standard is widely used by:

It is also an essential component in sensory proficiency and benchmarking programs, helping organisations maintain consistent testing conditions and ensure that all samples are evaluated objectively against a standard reference for the Cooked Onion flavour.

Other Information

Beer Flavour Wheel Number: 0736

Typical concentration seen- 0.05 – 0.3 ug / l

The standard recommended by Peppard (J Inst Brew, 91, 364-369).

FlavorActiV GMP Flavour Standards

Only Pharmaceutical Quality GMP Flavour Standards provide sufficient quality for professional sensory panels to train and validate with.

We produce encapsulated GMP (Pharmaceutical Good Manufacturing Practice) Flavour Standards that are safe to both smell and drink. The compounds within our capsules impart the aroma, taste and mouthfeel of a specific defect or positive flavour into a beverage for the purposes of taster training, calibration and quality control.

Our individual flavour GMP Flavour Standards are sold by flavour, each flavour pack contains 5 capsules, each separately blister packaged. Our sensory kits contain a mixture of flavours, each separately blister packaged, read the product description for flavour details.

We ship globally, and have over 20 years of experience at it. Our GMP Pharmaceutical Flavour Standards are produced to the highest standards, and as such, their shelf-life is strong and their quality consistent.

FlavorActiV’s flavour centre is the world’s only pharmaceutically run facility dedicated to the production of flavour reference standards. The Flavour Centre is a state-of-the-art facility housed within the campus of world-renowned Quay Pharma near Liverpool in the U.K.

The Flavour Centre was designed by FlavorActiV from the ground up at the direct request of global customers as they looked to move away from inferior food grade ‘certified flavour standards’ to GMP Pharma, a standard that ensures safe, stable, traceable, consistent and long shelf-life products.

All FlavorActiV’s industry-leading encapsulated flavour standards are manufactured following GMP at our Flavour Centre. All aspects of manufacture are overseen by Quay Pharma who are audited by the U.S. Food and Drug Administration (FDA) and the U.K. Medicines and Healthcare Products Regulatory agency (MHRA). We also welcome customer audits.

Only FlavorActiV GMP flavour standard capsules bear our mark of authenticity.

We brand each of our capsules so that our customers know they’re getting the Pharmaceutical GMP Quality that only FlavorActiV provide.

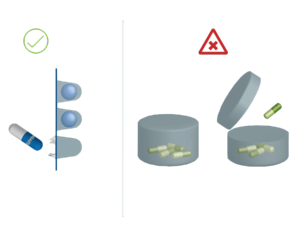

Industry leading packaging and shelf-life

FlavorActiV flavour standards are blister packaged, which extends shelf-life and protects capsules from potential contamination. The average shelf-life of FlavorActiV flavour standards is 18 months to 4 years, depending on the flavour compounds.

We will never ship in pots or plastic packaging, here’s why…

Blister packaging protects capsules from the environment until they are ready for use. Blister packaging greatly reduces the amount of headspace for possible flavour escape. As each capsule individually blister packaged, making use of one capsule still leaves all others protected. FlavorActiV Flavour Standard packaging is 100% recyclable, as opposed to polypropylene which is not widely recycled.

Pots are semi-porous, they allow molecules to pass through and flavour to be lost, their significant headspace also adds to substantial flavour escape as a gas, even when using just one capsule all those remaining in the pot are exposed.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.