-

1 × £75.00 GBP×

1 × £75.00 GBP×

Subtotal:

£75.00 GBP

Spicy flavour is one of a number of phenolic compounds that can occur in beer. Spicy is generated by yeast fermentation, and its presence can be positive if the flavour profile demands it. For beers with high alcohol content, spicy can have a serious impact character – overpowering other lighter flavours during a tasting.

FlavorActiVs Spicy Flavour Standard helps train professional tasters’ sensory skills to recognise the intensity of the spicy flavours in beers associated with eugenol, clove and allspice.

We ship globally – shipping costs may apply depending on your region

Minimum Order: £275

Spicy flavour is a sensory characteristic found in beer, attributed to phenolic compounds such as eugenol. It is primarily generated during yeast fermentation and can contribute positively to the overall flavour profile when balanced appropriately.

In beers with high alcohol content, the spicy flavour often becomes more pronounced, sometimes overpowering lighter, subtler notes. This makes it a key element for brewers and tasters to understand and control.

The spicy flavour in beer is caused by phenolic compounds, particularly eugenol, which is associated with clove and allspice aromas. These compounds are produced during the fermentation process by yeast.

Key factors influencing the presence of spicy flavour include :

Yeast strain : Certain strains are more likely to produce phenolic compounds.

Fermentation conditions : Temperature and fermentation duration impact the intensity of spicy notes.

Alcohol content : Higher alcohol levels amplify the perception of spicy flavours.

Spicy flavour is a natural component of most beers, though its intensity varies depending on the brewing process and style of beer.

The FlavorActiV Spicy Flavour Standard is a professional tool designed to train tasters to identify and evaluate the intensity of spicy flavours in beer. This standard is particularly useful for sensory training in breweries, quality control labs, and competitions.

By using this standard, tasters can :

Sensory terms : Recognise the specific vocabulary associated with spicy flavour.

Consistency : Develop reliability in identifying spicy notes across different beer styles.

Flavour balance : Enhance the ability to evaluate balance in high-alcohol beers.

To identify spicy flavour in beer, focus on these sensory terms :

Eugenol : A compound with a clove-like aroma, scientifically known as 2-methoxy-4-(2-propenyl)phenol.

Clove oil : Distinct, spicy, and warm aroma.

Allspice : Combination of clove, cinnamon, and nutmeg-like notes.

These terms are essential for professional tasters to accurately describe and evaluate the spicy flavour profile.

The Spicy Flavour Standard has several professional applications, including :

Brewing quality control : Ensures the desired balance of spicy notes in beer.

Sensory training : Helps tasters develop skills to identify and assess spicy flavours.

Product development : Assists brewers in crafting beers with specific flavour profiles.

Competitions and judging : Provides a reference for evaluating beers in professional settings.

By incorporating the Spicy Flavour Standard into sensory training programs, breweries and professionals can maintain consistency and improve the quality of their products.

Beer Flavour Wheel Number: 0111

Flavour level seen: 10 – 40 ug / l

Recommended flavour standard / sensory reference standard of: American Society of Brewing Chemists (ASBC) and the European Brewing Chemists (EBC)

FlavorActiV GMP Flavour Standards

Only Pharmaceutical Quality GMP Flavour Standards provide sufficient quality for professional sensory panels to train and validate with.

We produce encapsulated GMP (Pharmaceutical Good Manufacturing Practice) Flavour Standards that are safe to both smell and drink. The compounds within our capsules impart the aroma, taste and mouthfeel of a specific defect or positive flavour into a beverage for the purposes of taster training, calibration and quality control.

Our individual flavour GMP Flavour Standards are sold by flavour, each flavour pack contains 5 capsules, each separately blister packaged. Our sensory kits contain a mixture of flavours, each separately blister packaged, read the product description for flavour details.

We ship globally, and have over 20 years of experience at it. Our GMP Pharmaceutical Flavour Standards are produced to the highest standards, and as such, their shelf-life is strong and their quality consistent.

FlavorActiV’s flavour centre is the world’s only pharmaceutically run facility dedicated to the production of flavour reference standards. The Flavour Centre is a state-of-the-art facility housed within the campus of world-renowned Quay Pharma near Liverpool in the U.K.

The Flavour Centre was designed by FlavorActiV from the ground up at the direct request of global customers as they looked to move away from inferior food grade ‘certified flavour standards’ to GMP Pharma, a standard that ensures safe, stable, traceable, consistent and long shelf-life products.

All FlavorActiV’s industry-leading encapsulated flavour standards are manufactured following GMP at our Flavour Centre. All aspects of manufacture are overseen by Quay Pharma who are audited by the U.S. Food and Drug Administration (FDA) and the U.K. Medicines and Healthcare Products Regulatory agency (MHRA). We also welcome customer audits.

Only FlavorActiV GMP flavour standard capsules bear our mark of authenticity.

We brand each of our capsules so that our customers know they’re getting the Pharmaceutical GMP Quality that only FlavorActiV provide.

Industry leading packaging and shelf-life

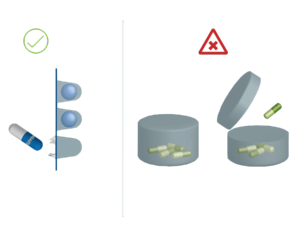

FlavorActiV flavour standards are blister packaged, which extends shelf-life and protects capsules from potential contamination. The average shelf-life of FlavorActiV flavour standards is 18 months to 4 years, depending on the flavour compounds.

We will never ship in pots or plastic packaging, here’s why…

Blister packaging protects capsules from the environment until they are ready for use. Blister packaging greatly reduces the amount of headspace for possible flavour escape. As each capsule individually blister packaged, making use of one capsule still leaves all others protected. FlavorActiV Flavour Standard packaging is 100% recyclable, as opposed to polypropylene which is not widely recycled.

Pots are semi-porous, they allow molecules to pass through and flavour to be lost, their significant headspace also adds to substantial flavour escape as a gas, even when using just one capsule all those remaining in the pot are exposed.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.