-

1 × £75.00 GBP×

1 × £75.00 GBP×

Subtotal:

£75.00 GBP

The Jasmine Flavour Standard, also known as Indole, is a GMP-certified sensory reference used for detecting jasmine off-flavour in beverages. It is widely applied in sensory training, quality control, and sensory panel validation across the beverage industry.

At controlled levels, jasmine aroma appears floral and sweet, but when caused by microbial contamination, it quickly becomes faecal, farmyard-like, and highly undesirable. The FlavorActiV Jasmine Flavour Standard allows trained panels to identify, measure, and control this off-flavour at extremely low detection thresholds.

We ship globally – shipping costs may apply depending on your region

Minimum Order: £275

The Jasmine flavour standard is designed to help beverage producers train sensory panels to accurately recognise and quantify jasmine (indole) contamination. When dosed into beverages, it recreates the exact sensory profile associated with coliform bacterial activity, enabling early fault detection before products reach consumers.

This standard is essential for:

– Routine sensory quality control

– Benchmarking jasmine off-flavour intensity

– Preventing microbial-related faults

– Standardising sensory vocabulary across panels

Jasmine flavour is a naturally occurring aromatic compound known as Indole. At very low concentrations, it presents as:

– Sweet

– Floral

– Slightly perfumed

At higher concentrations, however, it shifts dramatically into:

– Faecal

– Farmyard

– Septic

– Coliform-like aromas

This dual sensory character makes jasmine one of the most deceptive and critical off-flavours to monitor in beverage production.

Main Causes of Jasmine Off-Flavour:

– Coliform bacteria contaminating sugars and syrups

– Poor hygiene during fermentation

– Bacterial growth in processing equipment

– Cross-contamination during storage or transfer

Indole commonly appears alongside:

– DMS (Dimethyl Sulphide)

– DMTS (Dimethyl Trisulphide)

Together, these create a septic-like, heavily contaminated sensory profile.

The JASMINE flavour standard is used in regular sensory calibration programmes to ensure that panellists can:

– Detect jasmine at extremely low concentrations

– Recognise the transition from floral to faecal

– Differentiate jasmine from sulphur-based faults

– Accurately score intensity and persistence

WCR Lexicon Sensory Description

“An intense, slightly pungent, sweet, floral aromatic with underlying green, musty, dusty notes.”

Core Sensory Terms:

– Jasmine

– Faecal

– Farmyard

– Coliform

– Musty

– Septic

At low levels, jasmine is perceived as lightly floral.

At higher levels, it rapidly turns heavily faecal and offensive.

The Jasmine flavour standard is used by professionals across multiple beverage sectors, including:

– Breweries & Distilleries

– Soft Drink & Juice Manufacturers

– Flavoured Water Producers

– Ready-to-Drink Beverage Brands

– Sensory & Quality Assurance Laboratories

Key Applications:

– Sensory panel validation

– Shelf-life testing

– Microbial contamination detection

– Ingredient quality verification

– Production hygiene monitoring

Flavour Level: Variable – 5 – 15 ug / l

It is detected as jasmine at very low levels, but at high levels, it becomes more faecal.

Regular sensory training should identify jasmine off-flavours using our Jasmine GMP Flavour Standards for beverage quality control.

FlavorActiV refers to Jasmine as Indole.

FlavorActiV GMP Flavour Standards

Only Pharmaceutical Quality GMP Flavour Standards provide sufficient quality for professional sensory panels to train and validate with.

We produce encapsulated GMP (Pharmaceutical Good Manufacturing Practice) Flavour Standards that are safe to both smell and drink. The compounds within our capsules impart the aroma, taste and mouthfeel of a specific defect or positive flavour into a beverage for the purposes of taster training, calibration and quality control.

Our individual flavour GMP Flavour Standards are sold by flavour, each flavour pack contains 5 capsules, each separately blister packaged. Our sensory kits contain a mixture of flavours, each separately blister packaged, read the product description for flavour details.

We ship globally, and have over 20 years of experience at it. Our GMP Pharmaceutical Flavour Standards are produced to the highest standards, and as such, their shelf-life is strong and their quality consistent.

FlavorActiV’s flavour centre is the world’s only pharmaceutically run facility dedicated to the production of flavour reference standards. The Flavour Centre is a state-of-the-art facility housed within the campus of world-renowned Quay Pharma near Liverpool in the U.K.

The Flavour Centre was designed by FlavorActiV from the ground up at the direct request of global customers as they looked to move away from inferior food grade ‘certified flavour standards’ to GMP Pharma, a standard that ensures safe, stable, traceable, consistent and long shelf-life products.

All FlavorActiV’s industry-leading encapsulated flavour standards are manufactured following GMP at our Flavour Centre. All aspects of manufacture are overseen by Quay Pharma who are audited by the U.S. Food and Drug Administration (FDA) and the U.K. Medicines and Healthcare Products Regulatory agency (MHRA). We also welcome customer audits.

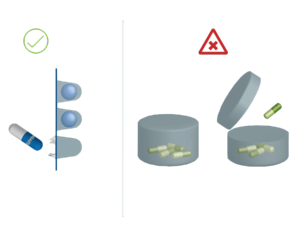

Only FlavorActiV GMP flavour standard capsules bear our mark of authenticity.

We brand each of our capsules so that our customers know they’re getting the Pharmaceutical GMP Quality that only FlavorActiV provide.

Industry leading packaging and shelf-life

FlavorActiV flavour standards are blister packaged, which extends shelf-life and protects capsules from potential contamination. The average shelf-life of FlavorActiV flavour standards is 18 months to 4 years, depending on the flavour compounds.

We will never ship in pots or plastic packaging, here’s why…

Blister packaging protects capsules from the environment until they are ready for use. Blister packaging greatly reduces the amount of headspace for possible flavour escape. As each capsule individually blister packaged, making use of one capsule still leaves all others protected. FlavorActiV Flavour Standard packaging is 100% recyclable, as opposed to polypropylene which is not widely recycled.

Pots are semi-porous, they allow molecules to pass through and flavour to be lost, their significant headspace also adds to substantial flavour escape as a gas, even when using just one capsule all those remaining in the pot are exposed.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.