-

1 × £75.00 GBP×

1 × £75.00 GBP×

Subtotal:

£75.00 GBP

The Fermented GMP Flavour Standard is a professional-grade sensory training tool designed for use in the beer and beverage industry. It enables accurate detection and evaluation of fermented off-flavours—commonly described as mouldy, rotten cheese, or musty—which arise from microbial contamination during production or shipping.

When added to beer or other beverages, this standard replicates the characteristic off-notes of uncontrolled fermentation. It is particularly relevant in identifying flavour faults caused by yeasts and bacteria in high-sugar environments, such as juice concentrates and sugar syrups.

Fermented GMP Flavour Standards are provided in powder form, packaged in single-dose gelatin capsules within a pharmaceutical-grade blister pack, for enhanced product stability and ease of use.

We ship globally – shipping costs may apply depending on your region

Minimum Order: £275

The fermented flavour is an off-flavour that emerges from microbial fermentation, primarily due to contamination by yeasts and bacteria. It is often perceived as rotten cheese, mouldy, fruity (undesirable), infected, or musty.

These flavours are not associated with intentional, beneficial fermentation but rather with uncontrolled spoilage. They typically develop when juice concentrates or sugar-rich products are poorly stored, especially during transit under suboptimal conditions.

Trained sensory professionals describe fermented off-flavours using the following terms :

– Mouldy

– Rotten Cheese

– Fruity (Spoiled)

– Infected / Musty

Recognising these descriptors is essential in quality control and product release decisions.

Fermented flavours typically occur due to the growth of microcontaminants like yeast and bacteria in products. These contaminants can be introduced during :

– Improper shipping and storage of juice concentrates.

– The presence of high-sugar environments, like sugar syrups, which are prone to fermentation.Fermentation can lead to a variety of undesirable flavours that need to be identified and controlled, especially in beverages.

The Fermented GMP Flavour Standard is crucial for professionals in the beverage industry as it supports sensory training and ensures accurate flavour evaluation. It helps validate sensory panels, ensuring that they can correctly identify a variety of off-flavours, including fermented flavours. This standard is part of a range of microbiological contamination off-flavours, such as acetic acid, lactic acid, and those resulting from alcohol fermentation, all of which can impact the quality of beverages.

The Fermented GMP Flavour Standard serves multiple critical applications across the beer and beverage industry, primarily in sensory training and validation of sensory panels. Sensory panels are groups of trained evaluators who assess the quality, taste, and flavour profiles of beverages.

The Fermented GMP Flavour Standard enables these professionals to identify and understand off-flavours, such as fermented, mouldy, or cheesy notes, which can arise from microbial contamination in beverage products.

This flavour standard has particular value in these professional applications :

– Brewmasters and beer tasters use it to identify and assess specific fermentation defects in their products.

– Quality control professionals in the beverage industry rely on it to maintain product standards and detect contamination issues.

– Sensory analysts utilise it for flavour evaluation of juices, syrups, and other sugar-based products to ensure quality consistency.

FlavorActiV GMP Flavour Standards

Only Pharmaceutical Quality GMP Flavour Standards provide sufficient quality for professional sensory panels to train and validate with.

We produce encapsulated GMP (Pharmaceutical Good Manufacturing Practice) Flavour Standards that are safe to both smell and drink. The compounds within our capsules impart the aroma, taste and mouthfeel of a specific defect or positive flavour into a beverage for the purposes of taster training, calibration and quality control.

Our individual flavour GMP Flavour Standards are sold by flavour, each flavour pack contains 5 capsules, each separately blister packaged. Our sensory kits contain a mixture of flavours, each separately blister packaged, read the product description for flavour details.

We ship globally, and have over 20 years of experience at it. Our GMP Pharmaceutical Flavour Standards are produced to the highest standards, and as such, their shelf-life is strong and their quality consistent.

FlavorActiV’s flavour centre is the world’s only pharmaceutically run facility dedicated to the production of flavour reference standards. The Flavour Centre is a state-of-the-art facility housed within the campus of world-renowned Quay Pharma near Liverpool in the U.K.

The Flavour Centre was designed by FlavorActiV from the ground up at the direct request of global customers as they looked to move away from inferior food grade ‘certified flavour standards’ to GMP Pharma, a standard that ensures safe, stable, traceable, consistent and long shelf-life products.

All FlavorActiV’s industry-leading encapsulated flavour standards are manufactured following GMP at our Flavour Centre. All aspects of manufacture are overseen by Quay Pharma who are audited by the U.S. Food and Drug Administration (FDA) and the U.K. Medicines and Healthcare Products Regulatory agency (MHRA). We also welcome customer audits.

Only FlavorActiV GMP flavour standard capsules bear our mark of authenticity.

We brand each of our capsules so that our customers know they’re getting the Pharmaceutical GMP Quality that only FlavorActiV provide.

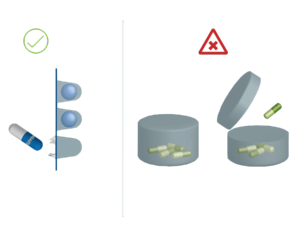

Industry leading packaging and shelf-life

FlavorActiV flavour standards are blister packaged, which extends shelf-life and protects capsules from potential contamination. The average shelf-life of FlavorActiV flavour standards is 18 months to 4 years, depending on the flavour compounds.

We will never ship in pots or plastic packaging, here’s why…

Blister packaging protects capsules from the environment until they are ready for use. Blister packaging greatly reduces the amount of headspace for possible flavour escape. As each capsule individually blister packaged, making use of one capsule still leaves all others protected. FlavorActiV Flavour Standard packaging is 100% recyclable, as opposed to polypropylene which is not widely recycled.

Pots are semi-porous, they allow molecules to pass through and flavour to be lost, their significant headspace also adds to substantial flavour escape as a gas, even when using just one capsule all those remaining in the pot are exposed.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.