-

1 × £75.00 GBP×

1 × £75.00 GBP×

Subtotal:

£75.00 GBP

Astringency is a characteristic of many beverages, created by polyphenols that react with proteins lining the mouth, producing a distinct astringent taste and a dry mouthfeel.

Our Astringent Flavour Standard for sensory training helps tasters recognise the dry, prickly, and ‘strident’ off-flavour in food and beverages resulting from excessive tannins.

This flavour standard contains a unique FlavorActiV formulation that differs from typical astringent tastes such as tannic acid and aluminium sulphate.

We ship globally – shipping costs may apply depending on your region

Minimum Order: £275

Astringency is a distinctive sensory characteristic found in many beverages, particularly those with high levels of tannins (polyphenols). This sensation occurs when tannins interact with proteins in the mouth, particularly those in saliva, creating a dry, puckering feeling and a bitter taste. The result is a prickly, tightening sensation on the palate, often described as the “drying” effect, similar to the feeling one experiences after drinking strong tea or red wine.

This dry mouthfeel is a hallmark of astringent flavours in various foods and beverages, including wine, tea, coffee, and some fruits. While this sensation can be desirable in moderation, excessive astringency is typically considered an off-flavour and can detract from the overall tasting experience.

The astringent taste occurs when compounds like tannins, which are polyphenolic substances, bind to proteins in the mouth. This leads to a dry, puckering sensation. The key causes of excessive astringency include :

– Tannins in wine, tea, or coffee : These beverages naturally contain high concentrations of tannins that create the characteristic astringent sensation.

– Excessive tannin content : When tannins are present in excessive amounts, they contribute to an overly dry or strident taste that can overwhelm the balance of other flavours.

– Reaction with proteins : Tannins interact with proteins in the saliva and the mucous membranes of the mouth, causing the sensation of dryness.

This astringent sensation can enhance certain beverages, like red wines. Still, if the level of astringency is too high, it can be considered an off-note that affects the overall sensory experience of the product.

In sensory analysis, calibrated tasting panels use astringency flavour standards to ensure a consistent and accurate assessment of astringent taste across different products. These standards are specially prepared reference samples with known levels of astringency, allowing panellists to recognise, measure, and describe the sensation with precision.

– Drying

– Tightening

– Tea dryness

The Astringent Flavour has diverse applications across multiple professional sectors :

– Sensory professionals use it for standardised flavour evaluation and assessment protocols

– Quality control professionals in the food and beverage industry rely on it to maintain product consistency and detect quality deviations.

– Brewers, winemakers, and tea producers utilise it to control and optimise astringency levels in their products.

– Professional tasters and training institutions incorporate it to calibrate their panels for consistent astringency assessments and develop detection skills.

– Researchers studying the sensory impacts of polyphenols in food and beverages use it as a reference standard for their investigations.

By using the Astringent Flavour Standard, professionals can accurately recognise, measure, and evaluate astringent flavours in beverages and foods, ensuring product quality and consistency.

Beer Flavour Wheel Number : 1340

Recommended flavour standard / sensory reference standard of : the American Society of Brewing Chemists (ASBC) and the European Brewing Chemists (EBC)

For more information on our range of GMP Flavour Standards and to place an order, please visit our online shop.

FlavorActiV GMP Flavour Standards

Only Pharmaceutical Quality GMP Flavour Standards provide sufficient quality for professional sensory panels to train and validate with.

We produce encapsulated GMP (Pharmaceutical Good Manufacturing Practice) Flavour Standards that are safe to both smell and drink. The compounds within our capsules impart the aroma, taste and mouthfeel of a specific defect or positive flavour into a beverage for the purposes of taster training, calibration and quality control.

Our individual flavour GMP Flavour Standards are sold by flavour, each flavour pack contains 5 capsules, each separately blister packaged. Our sensory kits contain a mixture of flavours, each separately blister packaged, read the product description for flavour details.

We ship globally, and have over 20 years of experience at it. Our GMP Pharmaceutical Flavour Standards are produced to the highest standards, and as such, their shelf-life is strong and their quality consistent.

FlavorActiV’s flavour centre is the world’s only pharmaceutically run facility dedicated to the production of flavour reference standards. The Flavour Centre is a state-of-the-art facility housed within the campus of world-renowned Quay Pharma near Liverpool in the U.K.

The Flavour Centre was designed by FlavorActiV from the ground up at the direct request of global customers as they looked to move away from inferior food grade ‘certified flavour standards’ to GMP Pharma, a standard that ensures safe, stable, traceable, consistent and long shelf-life products.

All FlavorActiV’s industry-leading encapsulated flavour standards are manufactured following GMP at our Flavour Centre. All aspects of manufacture are overseen by Quay Pharma who are audited by the U.S. Food and Drug Administration (FDA) and the U.K. Medicines and Healthcare Products Regulatory agency (MHRA). We also welcome customer audits.

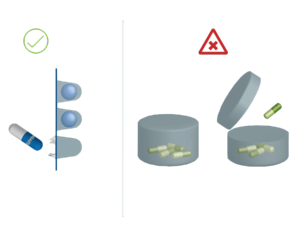

Only FlavorActiV GMP flavour standard capsules bear our mark of authenticity.

We brand each of our capsules so that our customers know they’re getting the Pharmaceutical GMP Quality that only FlavorActiV provide.

Industry leading packaging and shelf-life

FlavorActiV flavour standards are blister packaged, which extends shelf-life and protects capsules from potential contamination. The average shelf-life of FlavorActiV flavour standards is 18 months to 4 years, depending on the flavour compounds.

We will never ship in pots or plastic packaging, here’s why…

Blister packaging protects capsules from the environment until they are ready for use. Blister packaging greatly reduces the amount of headspace for possible flavour escape. As each capsule individually blister packaged, making use of one capsule still leaves all others protected. FlavorActiV Flavour Standard packaging is 100% recyclable, as opposed to polypropylene which is not widely recycled.

Pots are semi-porous, they allow molecules to pass through and flavour to be lost, their significant headspace also adds to substantial flavour escape as a gas, even when using just one capsule all those remaining in the pot are exposed.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.